Recent Posts

Shorr Collaborated With a Heavy-Duty Power Tool Manufacturer to Increase Sustainability and Efficiency in Their Packaging

A manufacturer of heavy-duty power tools was looking to decrease their total carbon dioxide emissions more than 60% by 2030 while increasing efficiency.

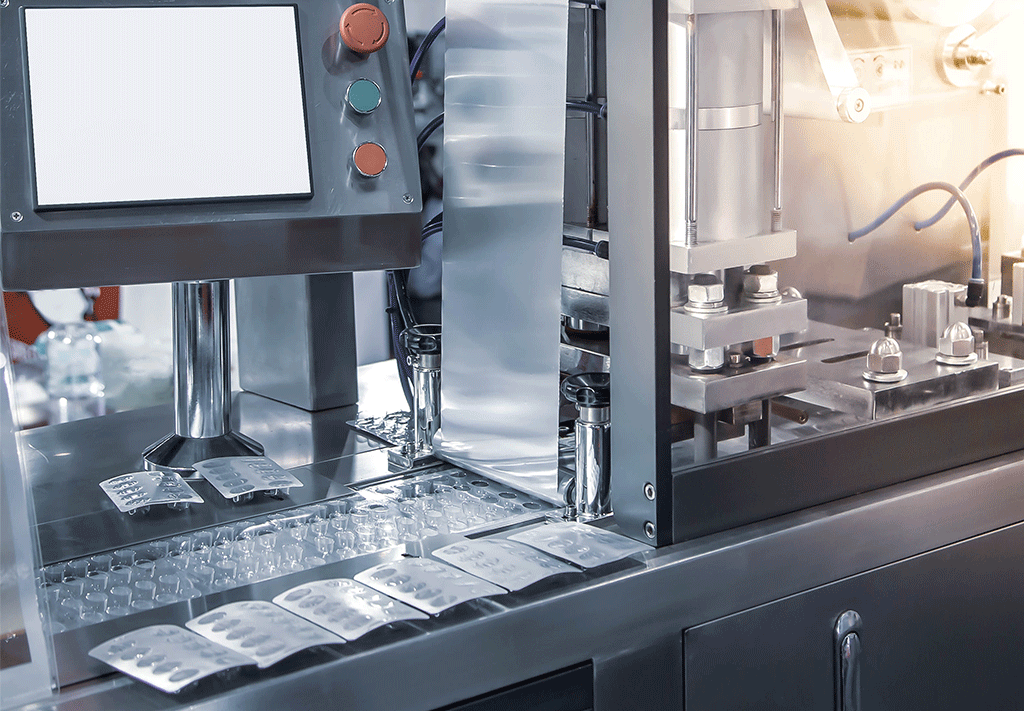

Shorr Partnered With a Medical Device Manufacturer to Streamline Packaging Materials at Their 3PL Locations

A medical device manufacturer was looking to manage packaging materials at their 3PL partner by optimizing on-hand inventory and reviewing current material capabilities.

All Posts

intellistock Helped a Powersports Company Unlock Value by Optimizing Operations and Forecasting Packaging Needs

A global leader in powersports, worked with Shorr to improve their supply chain management. Shorr’s vendor managed inventory solution, intellistock, provides usage data and trends allowing the customer to

Shorr Joined Forces With 3M to Streamline Operations for a Manufacturer and Distributor of Healthcare Supplies and Services

An American manufacturer and distributor of healthcare supplies was looking to increase throughput in their packaging operations. Shorr leveraged industry expertise and relationships with best-in-class suppliers to implement efficient

Shorr and Pregis Combine Efforts to Help a Major eCommerce Company Achieve Over $4.3 Million in Annual Savings

A retail marketing company was looking for a contract packaging partner on a large scale opportunity assembling and filling multi-vendor displays to be in store before the holiday season.

ShorrPack Solves Retailer’s Contract Packaging and Kitting Challenges During the Busy Holiday Season

A retail marketing company was looking for a contract packaging partner on a large scale opportunity assembling and filling multi-vendor displays to be in store before the holiday season.

Shorr Leveraged Co-Packing Capabilities to Resolve a CPG’s Bottleneck and Optimize Operations

A Consumer Packaged Goods company was experiencing setbacks in its manufacturing operations due to a packaging bottleneck. Shorr leveraged industry expertise and ShorrPack to offer cost-effective co-packing and kitting

Shorr Collaborated With 3M to Optimize an American Sportswear Retailer’s Material Usage and Ship-From-Store Solution.

An American sportswear retailer was suffering from setbacks in its packaging operations. Shorr leveraged its industry expertise and relationships with suppliers to implement efficient packaging practices.

Get more information