Equipment Labeling & Inkjet Printing Label Mill Label Applicators Label Mill LM4005 Automatic Apply System

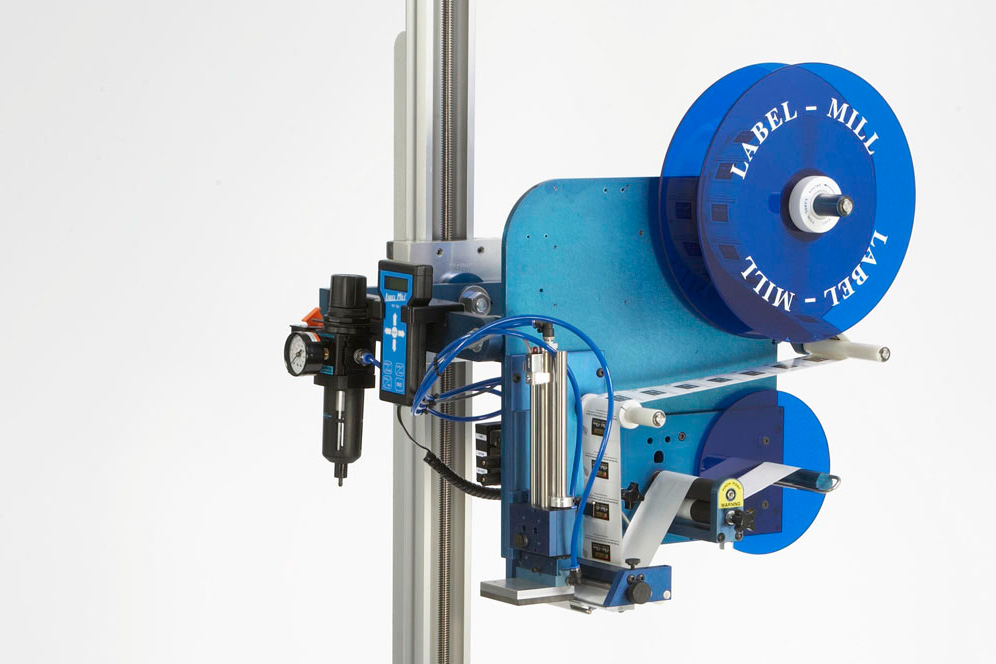

Label Mill LM4005 Automatic Apply System

Key Features

Overview

The Label Mill LM4005 label applicator system is high speed and heavy-duty.

Microprocessor controlled, the LM4005 has a unique modular design. This machine allows the standard peeler arm, tamp module, or a flag module.

Control features include all the hardware and software necessary to support the tamp, blow, wipe-on and flag applicator.

System has a two-line backlit display and the interface makes all configurations quick and easy.

Features

Label Mill 4005 Features:

- Speeds up to 1400 Inches a Minute

- Heavy Duty DC Drive

- Dynamic Motor Control

- 12 Inch Label Storage Spool Standard

- Heavy Duty Industrial Design

- User-Friendly Operating Software

- Automatic Set-Up

- Batch Counter

- Left and Right-Hand Designs

- Hand Held User Interface

- Optional System Status Light

Additional Options:

- Optional System Status Light Tower

- Optional Smart Tamp

- Optional Loose Loop Interface to Thermal Printer

Specifications

Label Mill 4005 Specifications:

- Labeling Speed/Rate: 1400 linear inches of web per minute standard

- Drive System: Heavy duty 1⁄8 hp DC drive motor

- Label Placement: Up to +⁄- 1⁄32” when labels are produced to specifications and product handling is controlled

- Electrical: 115 VAC/60Hz – 6 amps

- Label Roll Capacity: 12” maximum outside diameter wound on a 3” I.D. core.

- Air Requirements: 80 psi/3 cfm when equipped with tamp, flag, blow, swing, or corner wrap

- Label Size: Minimum 1⁄2” wide x 1⁄2” long. Maximum 61⁄2” wide x 12” long

- Application Method: Tamp, wipe-on, flag, blow, corner-wrap, and swing tamp

- Environment: Operating 50-95° F, 15-85% RH, non-condensing

- General Size: 25”W x 22”D x 21”H

- Weight: 60 lbs. with u-arm

- Product Sensors: Photoelectric or dry contact (mechanical limit switch)

- Additional Options: Left or right-hand models, custom systems

Maintenance

Shorr Packaging stands behind all the packaging equipment we represent, with a service network that extends throughout the contiguous U.S.

Our packaging automation specialists offer complete support for equipment selection, integration, installation, training, maintenance, 24/7 emergency service and parts procurement.

All of Shorr’s service technicians are factory certified and dedicated to ensuring that your packaging equipment is always operating at peak performance.