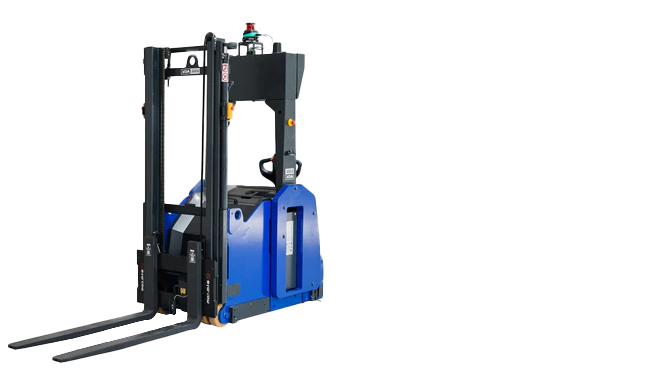

Equipment Global AGV L12

Global AGV L12

Key Features

Overview

The Global AGV L12 is a stand-alone logistics solution that can intelligently and innovatively index where and when the pallets should be collected, where they need to be delivered, and synchronize with other logistics processes.

The model is equipped with free forks that can be adjusted according to pallet size. In addition, it can handle pallets that are closed at the bottom and is also suitable for handling US, UK, and SEA pallets.

Features

- Allows your company to save up to 60% on simple pallet transport tasks

- Installed in 2-3 days

- Allows for quality control

- Prevents production stoppages and bottlenecks

- Can handle a variety of pallets

Specifications

Equipment Specifications

- Capacity: 1200 kg / 2645 lb

- Lift height: Max. 2844 mm. (112”)/ Limit: 1000 mm (39.4”)

- Fork dimensions: 40 x 100 x 1200 mm (1.6” x 3.9” x 47.2”)

- Between forks: Std. limit til 1000 mm (39,4”)

- Motor: 1.5 kW AC motor

- Transmission: Linde LAC transmission

- Max. speed: 1.2 m/s

* The maximum lifting height for standard operation is 1000mm (39.4″). It is possible to request a higher lift.

Pallet Specifications

- EUR-paller: 1200 x 800 x 144 mm (47.2″ x 31.5″ x 5.7″)

- Industrial pallets: 1200 x 1000 x 150 mm (47.2″ x 39.4″ x 5.9″)

- UK Block paller: 1200 x 1000 x 162 mm (47.2″ x 39.4″ x 6.4″)

- US Block paller: 219 x 1016 x 141 mm (48″ x 40″ x 5.6″)

- US Stringer paller: 1219 x 1016 x 130 mm (48″ x 40″ x 5.1″)

Other pallet sizes upon request

Safety Specifications

- 360° navigation system

- The Global AGV LGV12 constantly scans its surroundings to safely transport goods alongside people and among other equipment

- If the AGV’s route or safety zones are obstructed by an employee or something else, the AGV stops and keeps a safe distance. Once the object has been removed, the AGV automatically continues its route again.

Maintenance

Shorr Packaging stands behind all the packaging equipment we represent, with a service network that extends throughout the contiguous U.S.

Our packaging automation specialists offer complete support for equipment selection, integration, installation, training, maintenance, 24/7 emergency service and parts procurement.

All of Shorr’s service technicians are factory certified and dedicated to ensuring that your packaging equipment is always operating at peak performance.