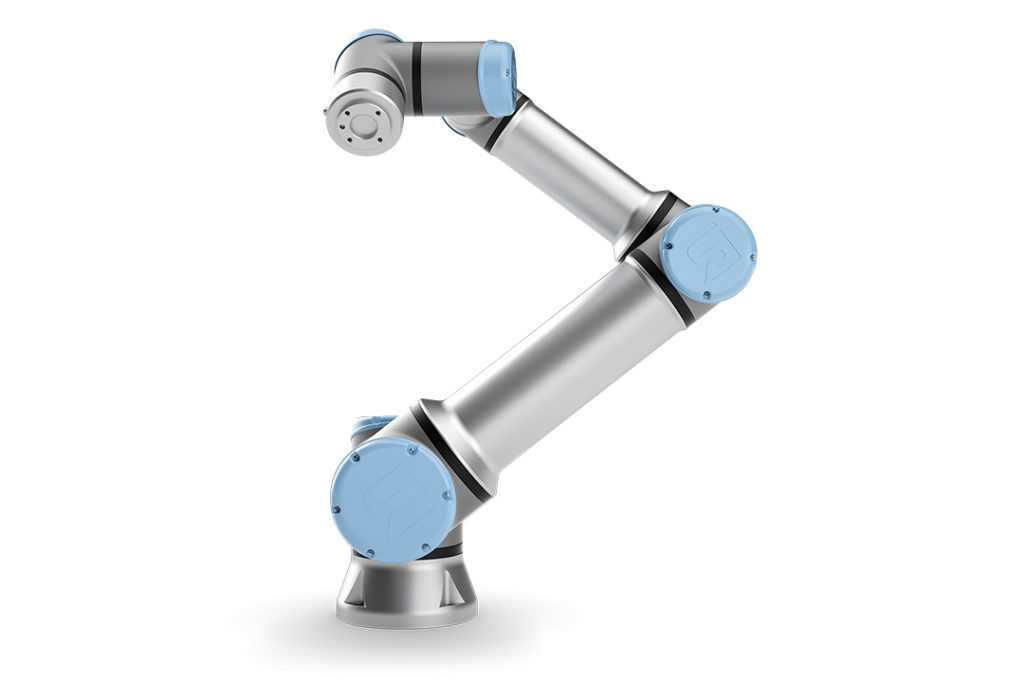

Equipment Collaborative Robots Universal Robots Cobot Arms Universal Robots UR16 / UR16e Collaborative Industrial Robot

Universal Robots UR16 / UR16e Collaborative Industrial Robot

Key Features

Overview

With an impressive 16kg (35.3 lbs.) of payload and a small footprint, this Universal Robots UR16e collaborative robot (cobot) equipment delivers a result that is ideal for heavy machine tending, material handling, packaging, and screw and nut driving applications. This machine shows a “powerhouse” arm, allowing for much heavier tooling and multi-part handling. Payload is very useful for lifting multiple parts in a single pick, making tasks much more efficient by achieving shorter cycle times.

Features

UR16e Quick Facts:

- Reach: 900 mm / 35.4 ins

- Payload: 16 kg / 35.3 lbs

- Footprint: Ø 190 mm

- Weight: 33.1 kg / 73 lbs

UR16e Features:

- Easy Programming: Technology allows operators with little to no programming experience to quickly set up and operate equipment.

- Fast Setup-up: Reduces typical deployment times from weeks to hours.

- Flexible Deployment: Lightweight, space-saving, and easy to re-deploy to multiple applications without changing production layout. Provides the agility to automate almost any manual task, including those with small batches or fast change-overs. The cobot is able to re-use programs for recurrent tasks.

- Collaborative and Safe: Machine takes on dirty, dangerous, and dull jobs to reduce repetitive strain and accidental injuries.

Specifications

MAIN

UR16e Specifications:

- Payload: 16 kg (35.3 lbs)

- Reach: 900 mm (35.4 in)

- Degrees of freedom: 6 rotating joints

- Programming: 12 inch touchscreen with polyscope graphical user interface

UR16e Performance:

- Power, consumption, maximum average: 585 W

- Safety: 17 configurable safety functions

UR16e Movement:

- Pose Repeatability per ISO 9283: ± 0.05 mm

- Typical TCP speed 1 m/s (39.4 in/s)

UR16e Features:

- Noise: Less than 65 dB(A)

- Robot mounting: Any Orientation

- I/O ports

- Tool I/O Power Supply Voltage: 12/24 V

- Tool I/O Power Supply: 2 A (Dual pin) 1 A (Single pin)

UR16e Physical:

- Footprint: Ø 190 mm

- Materials: Aluminium, Plastic, Steel

- Tool (end-effector) connector type: M8 | M8 8-pin

- Cable length robot arm: 6 m (236 in)

- Weight including cable: 33.1 kg (73 lbs)

- Operating temperature range: 0-50°C

- Humidity: 90%RH (non-condensing)

CONTROL BOX

UR16e Features:

- Ambient temperature range: 0-50°C

- I/O power supply: 24V 2A

- Communication: 500 Hz Control frequency

- Power source: 100-240VAC, 47-440Hz

- Humidity: 90%RH (non-condensing)

UR16e Physical:

- Control box size: (WxHxD) 475 mm x 423 mm x 268 mm (18.7 in x 16.7 in x 10.6 in)

- Weight: 12 kg (26.5 lbs)

- Materials: Powder coated steel

TEACH PENDANT

UR16e Features:

- Humidity: 90%RH (non-condensing)

- Display resolution: 1280 x 800 pixels

UR16e Physical:

- Materials: Plastic, PP

- Weight including 1m of TP cable: 1.6 kg (3.5 lbs)

- Cable length: 4.5 m (177.17 in)

Maintenance

Shorr Packaging stands behind all the packaging equipment we represent, with a service network that extends throughout the contiguous U.S.

Our packaging automation specialists offer complete support for equipment selection, integration, installation, training, maintenance, 24/7 emergency service and parts procurement.

All of Shorr’s service technicians are factory certified and dedicated to ensuring that your packaging equipment is always operating at peak performance.