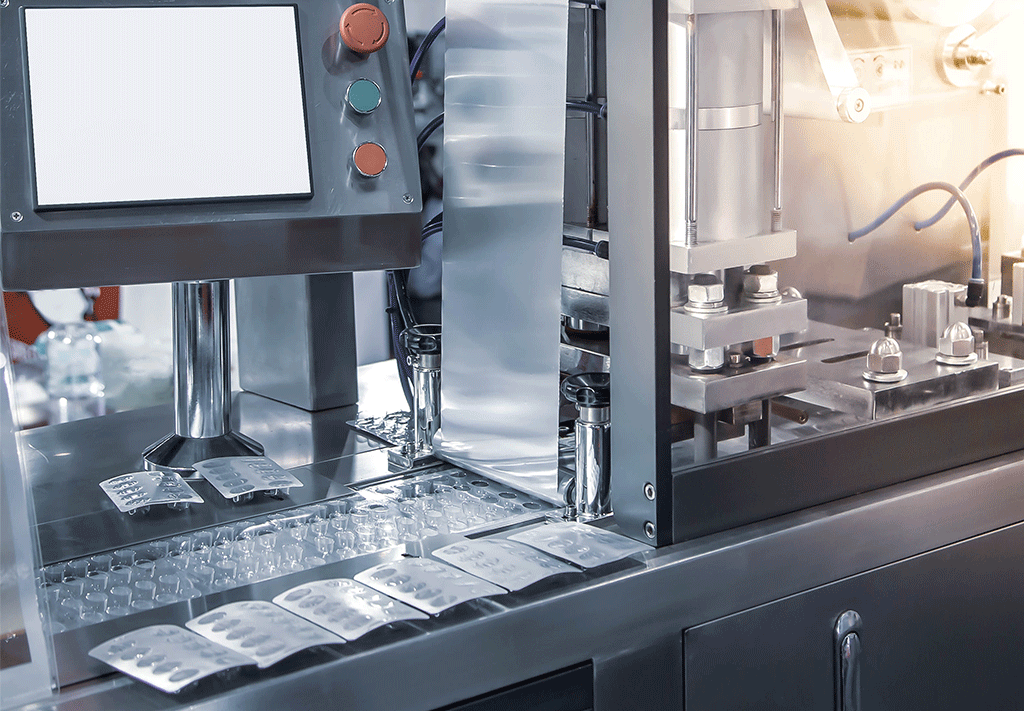

FOOD PACKAGING EQUIPMENT AUTOMATION

Shorr can supply your food packaging machinery needs from start to finish so that your solutions are complete, efficient, and cost-effective. Shorr’s Packaging Automation Group is experienced in virtually every area of the food packaging environment. We offer complete packaging equipment sales support for equipment selection, integration, installation, training, service, and parts procurement.

Primary Equipment

- Filling Systems & Vertical and Horizontal FFS

- Vacuum Chamber & Snorkel Machines

- Thermoforming Machines

- Side Pouch Systems

- Weigh Price Labeling Systems

- Stick Pack Machines

- Tray & Lid Packaging, Automatic and Semi-Automatic Skin Packaging Systems, & Shrink Bag Systems

- Induction Sealing Machines

- Scale/Weighing Systems

- MAP (Modified Atmosphere Packaging)

Secondary and Tertiary Equipment

- Case Sealers

- Case Erectors/ Tray Formers

- Case Formers

- Baggers and Bagging Systems

- Stretch Wrapping Equipment

- Shrink Wrapping Equipment

- Labeling and Inkjet Printing

- Strapping, Banding, Tying

- Workstations

- Cubing/ Weighing Systems

- Collaborative Robots

- Protective Packaging Equipment

Latest from our blog

Sustainability Packaging Myths Debunked

Shorr Collaborated With a Heavy-Duty Power Tool Manufacturer to Increase Sustainability and Efficiency in Their Packaging

Shorr Packaging Corporation earns Silver Badge from EcoVadis for Commitment to Sustainable Business Practices

Shorr Partnered With a Medical Device Manufacturer to Streamline Packaging Materials at Their 3PL Locations

intellistock Helped a Powersports Company Unlock Value by Optimizing Operations and Forecasting Packaging Needs

Recyclable vs Recyclability

Shorr Joined Forces With 3M to Streamline Operations for a Manufacturer and Distributor of Healthcare Supplies and Services

Shorr Is Awarded Pregis Awards in Recognition of Unwavering Commitment to Sustainability

EY Announces Rob Onorato of Shorr Packaging Corporation as an Entrepreneur Of The Year® 2023 Midwest Award Finalist

Paper vs. Plastic

Shorr and Pregis Combine Efforts to Help a Major eCommerce Company Achieve Over $4.3 Million in Annual Savings

Get more information